Imagine a world where the intricate control systems of vehicles, the smart devices in homes, and the machinery on factory floors operate with such precision that human intervention is barely needed. This is no longer a distant vision but a reality shaped by embedded systems automation. As industries grapple with the demand for faster development cycles and unyielding reliability, automation in embedded systems emerges as a game-changer. This review dives into the transformative potential of automation technologies, examining how they streamline processes, enhance performance, and redefine efficiency across diverse applications.

Key Features of Embedded Systems Automation

Embedded systems, specialized computing setups designed for specific tasks, often operate in real-time with minimal human oversight. These systems are the backbone of countless technologies, from automotive electronics to household gadgets. Automation enhances their development and deployment by tackling critical issues like efficiency and scalability. By reducing manual tasks, it ensures consistent performance and allows for rapid iterations, a necessity in today’s fast-paced tech landscape.

A standout feature of this technology is its integration of hardware and software solutions. Hardware control, achieved through circuit isolation techniques, uses components like optocouplers to manage configurations safely. This prevents electrical faults during testing, ensuring reliable manipulation of device states. Meanwhile, software tools automate repetitive tasks in the development lifecycle, significantly cutting down on errors and time spent on manual processes.

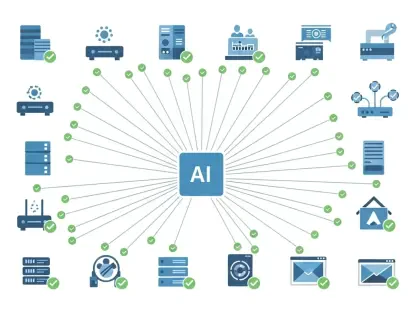

The adaptability of automation systems also shines through in their ability to handle multiple devices from a single control point. This scalability is vital for industries requiring simultaneous testing of various hardware setups. Such flexibility not only saves resources but also aligns with the diverse needs of modern technological environments, making automation a versatile tool in embedded systems development.

Performance Analysis and Methodologies

Delving into specific methodologies, circuit isolation stands out as a cornerstone of hardware automation. By employing components that separate control signals from the device under test, this technique safeguards against interference and electrical mishaps. Practical applications include controlling boot modes or reset functions, ensuring that hardware states are toggled with precision during automated testing phases.

On the software front, continuous integration and continuous deployment (CI/CD) pipelines, often powered by tools like Jenkins, revolutionize the development process. These systems enable remote command execution, build testing, and seamless deployment, accelerating iteration cycles. The result is improved code quality and a workflow that minimizes human error, allowing developers to focus on innovation rather than repetitive tasks.

Performance-wise, automation delivers measurable benefits in cost and time efficiency. Traditional methods, such as mechanical arms for hardware manipulation, are often prohibitively expensive and slow. In contrast, automation setups using affordable microcontrollers and isolation circuits offer a budget-friendly alternative. Their small footprint and compatibility with various communication protocols further enhance their appeal across different platforms.

Real-World Impact and Applications

The impact of embedded systems automation is vividly seen in industries like automotive, where control systems rely on precise, automated testing for safety and functionality. In consumer electronics, automation ensures that smart devices are developed and deployed with consistent quality, meeting the high expectations of users. Industrial machinery also benefits, as automated processes enable reliable operation under demanding conditions.

Specific implementations highlight the technology’s practicality. For instance, remote testing setups allow developers to manage hardware configurations without physical presence, a boon for distributed teams. Such setups can orchestrate complex tasks like programming boards or toggling switches, demonstrating how automation bridges geographical and logistical gaps in development workflows.

Unique use cases further underscore the technology’s versatility. Managing multiple devices under test from a centralized system not only boosts scalability but also mirrors real-world scenarios more accurately than simulations. This capability ensures that testing outcomes are relevant and reliable, providing a solid foundation for product deployment in critical applications.

Challenges in Adoption and Limitations

Despite its advantages, adopting automation in embedded systems is not without hurdles. The physical nature of hardware components, such as switches and jumpers, poses a significant challenge to full automation. Manually adjusting these elements for testing remains labor-intensive, and replicating real-world conditions in automated environments is often complex.

Cost considerations also play a role, as initial setups for automation can demand investment in specialized hardware and software. While solutions like mechanical arms exist, their expense and inefficiency limit widespread use. Additionally, reliance on development boards for simulations can skew results, failing to capture the nuances of actual hardware performance.

Efforts to address these issues are underway, with a focus on affordable hardware configurations and standardized protocols. Innovations aim to simplify integration and reduce costs, making automation accessible to a broader range of projects. However, until these challenges are fully resolved, adoption rates may remain uneven across industries with varying resource capacities.

Looking Ahead: Future Potential

The trajectory of embedded systems automation points toward exciting developments. Designing systems with built-in pin connections for seamless automation integration could eliminate cumbersome soldering tasks, streamlining setup processes. Such advancements would pave the way for standardized practices, easing the implementation of automation across diverse hardware platforms.

Anticipated breakthroughs include fully automated testing and deployment pipelines that further diminish human error. These systems promise to slash development timelines, allowing for rapid innovation in response to market demands. As these technologies mature, their precision and efficiency are expected to redefine benchmarks in embedded systems development over the coming years.

The long-term impact on industries cannot be overstated. Sectors dependent on embedded systems stand to gain from enhanced operational accuracy and reduced costs. As automation becomes more ingrained, it will likely catalyze a shift toward smarter, more responsive technologies, fundamentally altering how products are conceived, tested, and brought to market.

Final Thoughts

Reflecting on this exploration, embedded systems automation proves to be a transformative force, blending hardware precision with software agility to redefine development landscapes. Its ability to enhance efficiency and reliability leaves a lasting impression on various industries. Moving forward, stakeholders should prioritize investment in cost-effective solutions and standardized protocols to overcome existing barriers. Collaboration between hardware designers and software developers will be crucial to integrate automation seamlessly into future systems. By focusing on these actionable steps, the tech community can unlock the full potential of this technology, ensuring that innovation continues to thrive in an increasingly automated world.