Setting the Stage for a Testing Transformation

In the fast-paced world of semiconductor design, analog circuitry testing has long been a bottleneck, draining resources and extending timelines with its labor-intensive processes. Imagine a scenario where months of manual coding and reliance on prohibitively expensive mixed-signal test equipment stand between innovation and market delivery, creating persistent challenges that have plagued integrated circuit (IC) designers and often delayed critical advancements in electronics and automotive sectors. Siemens’ latest offering, a pioneering tool in the realm of analog testing, steps in to address these pain points with unprecedented automation and efficiency, promising to reshape how the industry approaches this complex task.

The significance of this technology cannot be overstated in an era where time-to-market is a key competitive edge. By slashing testing durations from months to days, this software introduces a paradigm shift that aligns with the industry’s urgent need for speed without compromising quality. This review delves into the capabilities of this groundbreaking solution, exploring how it tackles historical inefficiencies and sets new standards for analog IC testing.

Unpacking the Core Features

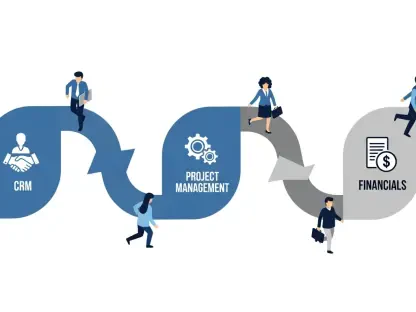

Automated Design-for-Test Excellence

At the heart of this software lies its distinction as the first fully automated design-for-test (DFT) solution tailored for analog circuitry. It generates minimal-impact DFT structures and digital test patterns adaptable to nearly any analog circuit block, streamlining what was once a tedious manual process. This automation drastically reduces the time spent on test coding, enabling engineers to focus on design innovation rather than repetitive tasks.

Beyond simplifying workflows, the tool achieves sub-millisecond test execution on standard equipment, a feat that redefines operational speed in testing environments. This capability ensures that IC designers can iterate quickly, verifying functionality with efficiency that traditional methods could never match. The result is a significant boost in productivity, setting a new benchmark for the semiconductor landscape.

Leveraging Digital ATE for Cost Efficiency

One of the standout advantages of this technology is its integration with digital automated test equipment (ATE), a cost-effective alternative to traditional mixed-signal testers. By utilizing digital ATE, the software cuts down on the high expenses associated with specialized hardware, making advanced testing accessible to a broader range of companies. This democratization of testing resources is a game-changer for smaller firms and startups in the IC design space.

Moreover, the tool delivers exceptional defect coverage, surpassing 90% as per IEEE P2427 standards, while completing verification of circuit blocks in mere hours instead of weeks. Such performance not only saves money but also accelerates the design cycle, allowing for faster iterations and refinements. This balance of affordability and reliability positions the software as a vital asset for cost-conscious yet quality-driven organizations.

Standards Compliance and Simulation Support

Compatibility with industry standards further enhances the software’s appeal, as it adheres to IEEE P1687.2 guidelines, supporting high-level test descriptions like ICL and PDL for simulation testbenches. This ensures seamless integration into existing workflows, providing a robust framework for tasks such as algorithmic trimming and parametric testing. Designers can rely on these features to maintain precision across diverse testing scenarios.

Additionally, the software aligns with ISO 26262 functional safety requirements, a critical factor for applications in automotive and other safety-sensitive industries. Its ability to simulate and verify defect coverage up to 1,000 times faster than specification-based tests underscores its role as a versatile and forward-thinking solution. This adaptability makes it an indispensable tool for meeting stringent regulatory demands.

Performance in Real-World Contexts

Adoption by Industry Pioneers

Early adopters in the IC design sector have already begun integrating this technology into their processes, addressing long-standing issues of time, cost, and complexity. Feedback from these partners highlights how the software streamlines testing phases, offering reliable outcomes well before silicon production begins. Such practical benefits are crucial for maintaining competitive edges in rapidly evolving markets.

The impact extends across various applications, from consumer electronics to automotive systems, where functional safety compliance is non-negotiable. By providing a unified approach to testing, the tool helps ensure that designs meet rigorous standards without the usual delays. This real-world validation underscores its potential to transform operational norms across diverse industries.

Navigating Implementation Challenges

Despite its promise, adopting this new automated workflow presents certain hurdles, including a learning curve for teams accustomed to traditional methods. Compatibility with legacy systems also poses concerns, as some organizations may require significant updates to fully leverage the software’s capabilities. These barriers, though not insurmountable, warrant careful consideration during deployment.

Ongoing industry debates about balancing speed with accuracy further complicate the adoption landscape, alongside potential technical or regulatory constraints. Siemens is actively refining the tool to address these issues, ensuring that enhancements mitigate risks and improve user experience. This commitment to continuous improvement reflects a proactive stance toward widespread acceptance.

Industry Trends and Market Implications

Shift Toward Automation and Integration

The semiconductor industry is witnessing a marked shift toward automation and digital integration in analog testing, driven by the need for faster, more efficient solutions. This trend aligns with broader goals of reducing time-to-market while upholding high-quality standards, a priority echoed by industry leaders. The introduction of this software exemplifies how technology can bridge longstanding gaps in testing methodologies.

Expert insights, such as those from Ankur Gupta of Siemens Digital Industries Software, emphasize the critical role of rapid test outcomes paired with superior defect coverage. This perspective highlights a collective push to innovate testing practices, ensuring that speed does not come at the expense of reliability. The software stands as a testament to this evolving ethos, paving the way for future advancements.

Broader Impact on Semiconductor Innovation

As automation becomes the norm, tools like this are poised to influence how IC designs are validated, potentially accelerating innovation cycles across sectors. The ability to conduct thorough testing in a fraction of the time opens doors for more experimental designs, fostering creativity without the burden of extended delays. This ripple effect could redefine product development timelines industry-wide.

Furthermore, the cost savings associated with digital ATE integration enable reinvestment into research and development, fueling further technological progress. The convergence of efficiency and affordability suggests a future where testing no longer hinders but rather propels semiconductor advancements. This dynamic positions the industry for sustained growth and adaptability.

Looking Ahead: Future Potential

Expanding Technological Horizons

Looking forward, this software holds promise as a transformative force in analog testing, with plans for broader market availability already in motion. Potential advancements include deeper integration with emerging technologies, such as AI-driven analytics, to further enhance test precision. Such developments could redefine the scope of what automated testing can achieve.

Support for newer IC designs and architectures is another area of anticipated growth, ensuring relevance as industry needs evolve. Over the coming years, from 2025 to 2027, iterative updates are expected to address niche requirements, broadening the tool’s applicability. This forward-looking approach signals a commitment to staying ahead of design trends.

Long-Term Industry Benefits

The long-term implications point to a significant reduction in time-to-market, a critical metric for competitive success in electronics and beyond. Enhanced productivity through streamlined testing processes will likely become a standard expectation, reshaping how companies allocate resources. This shift could catalyze a new era of efficiency in semiconductor manufacturing.

Moreover, as functional safety remains a priority, the software’s compliance features will continue to play a pivotal role in high-stakes applications. Its influence on maintaining rigorous standards while accelerating workflows suggests a lasting impact on industry practices. The trajectory indicates a tool that will remain integral to future innovations.

Final Reflections and Next Steps

Reflecting on the evaluation, it is evident that Siemens’ solution marks a significant leap forward in analog IC testing, with its remarkable speed and cost-effectiveness standing out as key strengths. The high defect coverage achieved, often exceeding 90%, paired with the ability to complete tests up to 100 times faster than traditional methods, underscores its value to the industry. Despite initial challenges in adoption and integration, the refinements made during early deployments demonstrate a promising foundation for broader use.

Moving forward, stakeholders should prioritize comprehensive training programs to ease the transition to automated workflows, ensuring teams are well-equipped to harness the tool’s full potential. Exploring partnerships for tailored compatibility solutions with existing systems could further mitigate implementation barriers. As the industry continues to evolve, keeping an eye on emerging standards and technological synergies will be crucial to maximizing the benefits of this innovative testing solution.