In a world where manufacturing is defined by speed, complexity, and razor-thin margins, the role of enterprise technology is being completely reimagined. We’re joined today by Anand Naidu, a renowned development expert at the forefront of this transformation. He brings a deep understanding of how advanced AI is moving ERP systems beyond simple record-keeping to become active partners in the manufacturing process. In our conversation, we will explore the practical impact of Agentic AI on the factory floor, discussing how these intelligent “champions” are designed to autonomously execute tasks, guide decisions for lean teams, and deliver tangible financial results. We’ll also delve into the critical aspects of building trust through explainability and governance, and look ahead at how this technology will reshape the industry.

You’ve distinguished Agentic AI as a “system of action” rather than just analysis. Beyond recommending actions, how does a “Productivity Champion” autonomously execute routine tasks, and what is a specific example of a background workflow it fully manages without human intervention?

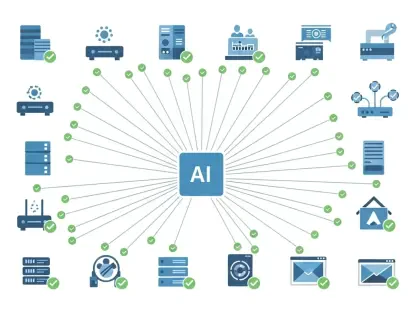

That’s the fundamental shift we’re talking about—moving from passive analysis to active participation. A Productivity Champion isn’t just a smarter report; it’s a digital teammate handling the thankless, repetitive work that consumes so much of your team’s day. Imagine a workflow for a routine material replenishment order. Instead of a person constantly monitoring stock levels, running reports, and manually creating a purchase request, the agent does it all. It senses when a specific component on the line is projected to fall below a safety threshold, validates this against the current production schedule, and then autonomously generates and places the internal transfer order to move stock from the main warehouse to the line-side bin. This all happens in the background, without a single click, freeing up that planner to manage a real supply chain exception rather than just pushing paper.

For a Line Lead Champion preparing for a shift, what specific data sources does it use to predict top losses? Could you walk us through the process from the agent flagging a risk to it initiating a maintenance work order, and explain the human approval step?

The Line Lead Champion is all about giving frontline teams a head start, so they aren’t walking into a shift blind. It taps into a rich stream of real-time and historical data—everything from the current production schedule and upcoming changeover requirements to historical performance data on that specific line and even known equipment health or quality alerts. It uses machine learning to see patterns, predicting that, for example, a specific machine tends to cause micro-stoppages after a long run of a certain product. When it flags this risk, the process becomes collaborative. The agent will surface a notification directly within the line lead’s connected worker application, saying something like, “High probability of feeder jams on Machine 4 within the next two hours based on recent performance. Recommend proactive maintenance.” From there, it can pre-populate a maintenance work order with all the necessary details. The human approval step is critical for trust; the line lead reviews the recommendation, perhaps adds a quick note, and with a single tap, approves it. The agent then routes the order, but the decision and control remain firmly with the person on the floor.

Mid-market manufacturers often operate with lean IT teams. How does Champion AI avoid becoming another complex project for them? Could you describe the user experience for a planner and how the system’s “ambient” nature guides them through a complex inventory optimization decision?

This was a core design principle for us. We knew that for this to be valuable in the mid-market, it couldn’t require a dedicated data science team to run it. The intelligence is embedded directly into the QAD Adaptive ERP workflows they already use every day, not in some separate, complicated analytics tool. For a planner, the experience feels more like having a seasoned expert looking over their shoulder. They aren’t configuring algorithms; they’re just doing their job. For instance, an Optimization Champion might notice that demand for a certain product has been trending down while safety stock levels have remained high. Instead of the planner having to dig for this insight, a prompt will appear naturally within their planning screen. It will say, “We’ve noticed a sustained demand shift for product XYZ. You could potentially free up significant working capital by adjusting safety stock. Here’s a suggested change.” It presents the ‘why’ and the potential impact in plain language, turning a complex data analysis problem into a simple, guided decision. That “ambient” nature is key—the system steps in to help at the right moment, without making the user feel like they’re operating a complex AI.

As AI makes more operational decisions, trust is critical. How do you ensure Champion AI’s recommendations are explainable to a plant manager? What specific safeguards prevent it from acting outside established business rules, and how does the human feedback loop actually tune its behavior over time?

Trust is everything, and you don’t earn it with a “black box.” Our first principle is that every recommendation is grounded in the customer’s own data and context. When an agent suggests an action, we make it clear what signals it’s reacting to. It’s not a vague guess; it’s a conclusion based on specific events in their own operation. The most important safeguard is that agents are constrained by the configured business rules and workflows of the ERP. They learn how you make things, what your quality standards are, and what your operational boundaries are, and they are programmed to stay within that frame. The second, and most critical, safeguard is human oversight. The system proposes, but the people decide. That human feedback loop is an active tuning mechanism. When a plant manager accepts, modifies, or rejects a recommendation, the agent learns from that decision. This ensures the AI’s behavior remains aligned not just with the written rules, but with the practical wisdom of how you actually want to run your plant.

You’ve noted an early adopter saved $300,000 in working capital. Can you detail the specific inventory adjustments the Optimization Champion identified? What was the process that allowed this customer to achieve such value within a 90-day deployment, a very rapid timeline for ERP?

That was a fantastic win and a perfect example of the agent’s power. The Optimization Champion was continuously analyzing their demand signals, supply constraints, and on-hand inventory. It identified several pockets of slow-moving or obsolete inventory that were tying up cash but weren’t immediately obvious in standard reports. It also flagged finished goods where the safety stock levels were calibrated for a demand pattern that had shifted months ago. By presenting these specific, actionable recommendations—like reducing safety stock on three key product lines and initiating a clearance plan for a dozen obsolete components—the customer could act immediately. The reason they saw that value in just 90 days, which is almost unheard of for an ERP project, is because our AI-assisted migration agents streamlined the deployment itself. These Implementation Champions guide teams through the process, automate setup, and remove friction, so customers get to the value much, much faster.

With the recent acquisition of Kavida.ai, how will its technology accelerate the Champion AI roadmap? Can you share an example of a new, role-specific agent we might see in the next year and describe the “messy reality” of the factory floor it will be designed to handle?

The acquisition of Kavida.ai is a massive accelerator for us because they are experts in applying Agentic AI to the complex, often chaotic, world of industrial supply chains. It will help us build more specialized agents, faster. Looking ahead, you could absolutely see an agent specifically designed for a Quality Manager. This agent wouldn’t just flag defects after they happen; it would be designed to handle the “messy reality” of preventative quality. For instance, it could correlate subtle changes in raw material batches from a supplier with downstream micro-stoppages on the production line—a connection that’s nearly impossible for a human to spot in real time. It would then proactively alert the Quality Manager before the issue escalates into a full-blown quality hold, allowing them to adjust machine calibrations or flag the material for inspection. It’s about getting ahead of the problems that bubble up from the complex, interconnected, and often unpredictable nature of the factory floor.

What is your forecast for the manufacturing technology landscape over the next three years?

I believe we are at a major turning point. The era of ERP systems as passive databases is ending, and we are rapidly moving toward systems that actively participate in the operation. Static dashboards and historical reports will no longer be enough. The expectation from manufacturers will be that their core software understands their unique processes and can work alongside their teams in real time, almost like a digital colleague. You’re going to see a much greater focus on role-based intelligence that is deeply embedded in the workflow, addressing the “messy reality” of how work actually gets done. The platforms that succeed will be those that masterfully combine a rock-solid, reliable system of record with a smart, responsive agentic layer that can sense what’s happening, help decide the next best action, and drive that action right in the flow of work.