New Holland has recently unveiled IntelliSense Sprayer Automation, a cutting-edge system set to transform agricultural productivity and efficiency. This advanced technology is designed for the Model Year 2026 Guardian series front boom sprayers, specifically the SP310F, SP370F, and SP410F models. IntelliSense Sprayer Automation offers a comprehensive range of application functions suitable for various crops, including corn, soybeans, cotton, and small grains, without any annual subscription or per-acre fees, making it a standout in the market.

Advancements in Agricultural Technology

IntelliSense Sprayer Automation is the latest addition to New Holland’s suite of automation solutions, complementing existing technologies in harvest and baler automation. Curtis Hillen, cash crop segment lead for New Holland North America, emphasizes the system’s ability to enhance productivity, efficiency, and application quality for Guardian front boom sprayers through live variable rate and selective spray modes. This innovative technology not only addresses the needs of modern farmers but also exemplifies New Holland’s dedication to improving the agricultural sector by providing state-of-the-art solutions.

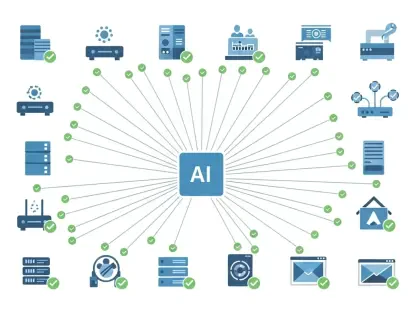

A unique feature of IntelliSense Sprayer Automation is the SenseApply Camera Unit, which replaces the multiple boom-mounted cameras typically used in smart apply technologies. Mounted high atop the cab, the SenseApply camera scans field conditions up to 50 feet ahead across the entire boom width, allowing for faster and more accurate assessments. This advanced vantage point ensures that inputs are applied more accurately and swiftly, contributing to optimal crop health and yield. Additionally, this streamlined approach simplifies the operator’s tasks, enabling them to focus on other aspects of farm management.

Selective Spray Capabilities

One of the key functions of IntelliSense Sprayer Automation is its Selective Spray capability, which includes Spot Spraying and Base + Boost application types. Spot Spraying uses green-on-brown technology to detect and target small-stature weeds under two inches high, activating corresponding nozzles for precise weed control. This targeted approach maximizes the efficacy of herbicides and minimizes environmental impact by reducing overapplication and chemical runoff. As agricultural practices evolve, such precision technologies become increasingly vital for sustainable farming.

The Base + Boost function applies a uniform base rate of herbicide across the entire boom width while activating an additional boost rate from designated nozzles where larger weeds are detected. This ensures more effective weed control by tailoring the herbicide application to varying weed sizes and densities. By providing customized treatment, IntelliSense Sprayer Automation addresses the diverse needs of different crops and helps farmers achieve optimal results without compromising efficiency or crop health. The ability to adapt to field conditions in real time demonstrates the system’s superior capability in managing weed populations.

Customizable Application Sensitivity

Selective Spray allows operators to customize the sensitivity and coverage area, adjusting responsiveness to different weed sizes and setting target application areas precisely where weeds are detected. This customization optimizes herbicide usage and enhances application efficacy. Operators can fine-tune the system to suit the specific requirements of their fields, ensuring a more effective and economical use of inputs. This ability to personalize settings ensures that resources are used judiciously, leading to better management of environmental impacts and farm costs.

In addition to Selective Spray, IntelliSense Sprayer Automation features live variable rate application (VRA) capabilities that optimize inputs like nitrogen, plant growth regulators (PGR), fungicides, and harvest aids based on real-time assessments of plant biomass health. These sophisticated features allow for fine-tuning application rates automatically, removing guesswork from the equation and reducing wastage. This data-driven approach to farming ensures that every application is backed by objective measurements instead of subjective judgment, fostering precision and accuracy in crop management.

Financial and Operational Benefits

Field trials conducted by Kansas State University and CNH have demonstrated significant cost savings with IntelliSense Sprayer Automation, particularly in nitrogen applications. The system’s accurate plant biomass health assessments and variable rate applications resulted in a 10% reduction in nitrogen usage compared to a constant broadcast rate. This precise application method conserves valuable resources and translates to substantial financial savings for farmers. By leveraging IntelliSense Sprayer Automation, farmers can achieve more efficient input utilization, reducing costs and improving overall profitability.

Efficient use of inputs not only translates to cost savings but also extends the operating range of sprayer tanks, reducing the frequency of refills. This leads to increased operational efficiency and reduced downtime for farmers. With fewer interruptions for refilling, sprayers can cover more acres in less time, enhancing productivity. This streamlined process ensures that farmers can meet their application schedules more promptly, optimizing the timing of treatments for maximum effectiveness. The operational benefits of the system, combined with its financial advantages, provide a compelling case for its adoption in modern farming practices.

Enhanced Speed and Performance

IntelliSense Sprayer Automation allows sprayers to operate at industry-leading speeds, with VRAs functioning at up to 25 mph and Selective Spray at up to 19 mph. This high-speed capability ensures that applications are performed quickly and efficiently without compromising quality. The ability to maintain high performance at such speeds is particularly beneficial during critical farming periods when timely applications are crucial for crop health and yield. By offering robust performance under demanding conditions, IntelliSense Sprayer Automation stands out as a reliable tool for modern agriculture.

The system’s comprehensive capabilities make it suitable for a wide range of crops, including corn, soybeans, wheat, barley, canola, cotton, small grains, edible beans, and other legumes. This versatility further enhances its value for farmers. Whether dealing with diverse crop types or varying field conditions, the system’s adaptability makes it an indispensable asset. Its broad application range means farmers can invest in a single system that meets multiple needs, increasing their return on investment and simplifying their equipment portfolio.

A Full-Season Solution

New Holland has recently launched IntelliSense Sprayer Automation, an innovative system poised to boost agricultural productivity and efficiency. This state-of-the-art technology is specifically designed for the Model Year 2026 Guardian series front boom sprayers, particularly the SP310F, SP370F, and SP410F models. IntelliSense Sprayer Automation delivers a full spectrum of application functions that cater to a diverse range of crops, including corn, soybeans, cotton, and small grains. What sets this system apart is that it does not require any annual subscription or per-acre fees, making it a unique offering in the market. By eliminating these extra costs, New Holland ensures that farmers can take advantage of advanced technology without worrying about additional financial burdens. This development signifies a considerable advancement in agricultural technology, promising to make farming more efficient, cost-effective, and productive for a variety of crops.